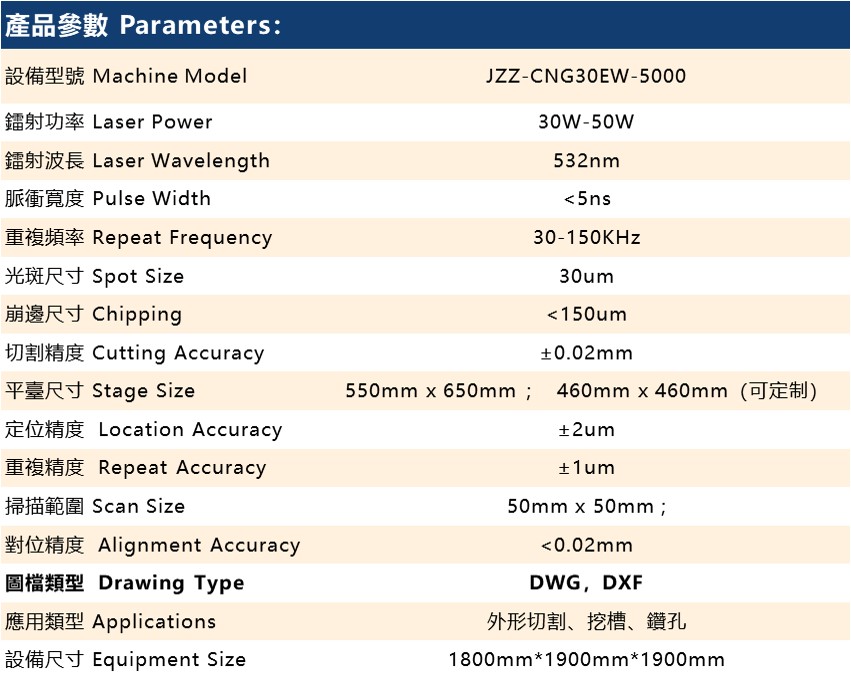

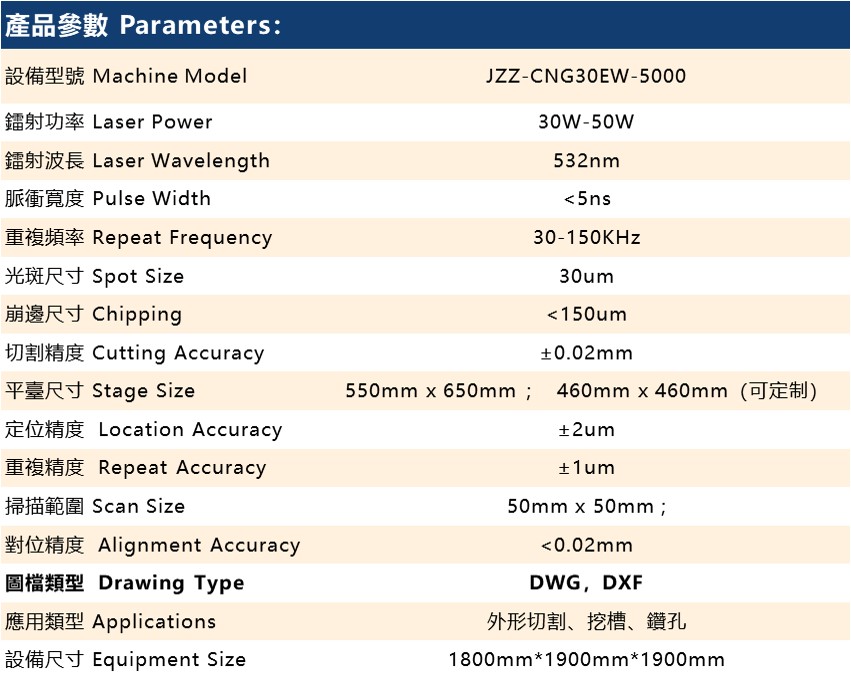

This machine is mainly used for shape cutting and drilling of glass products. It can be widely used in 3C and glass cover earphone hole, camera hole, operation panel and other products for high quality window opening, drilling and slotting. Compared with traditional processes, it can greatly improve cutting efficiency and yield.

設備特點Equipment Feature:

Ø大理石精密平臺:穩定性高、耐腐蝕、無形變、精度高;

Ø獨立光路系統設計:針對玻璃鑽孔特性設計了獨特的光學與防塵系統;

Ø高性能運動平臺:直線電機搭配精密補償,實現高精度加工;

Ø智慧視覺應用:CCD自動對位識別各類Mark點,自動聚焦,高精度識別系統;

Ø操作管理系統:產線操作監控,參數記錄、切割效率等功能;

Ø真空廢氣處理系統:真空平臺吸附腔體保證產品的平整性,減少產品熱效應和粉塵污染;

Ø專業的治具設計:因應玻璃行業特點,設計了專門的防塵與防鐳射損傷治具;

Ø智慧化軟體系統:自動對位,防呆報警,精度自動校正,自動聚焦等功能;

ØMarble precision platform: high stability, corrosion resistance, no deformation, high precision;

ØIndependent optical system design: unique optical and dustproof system for glass drilling characteristics;

ØHigh-performance motion platform: linear motor with precision compensation for high-precision machining;

ØIntelligent vision application: CCD automatic alignment to identify various types of Mark points, auto focus, high-precision identification system;

ØOperation management system: production line operation monitoring, parameter recording, cutting efficiency and other functions;

ØVacuum exhaust gas treatment system: vacuum platform adsorption cavity to ensure product flatness, reduce product thermal effects and dust pollution;

ØProfessional fixture design: In response to the characteristics of the glass industry, special dust and laser damage prevention fixtures have been designed.

ØIntelligent software system: automatic alignment, anti-dull alarm, automatic correction of accuracy, auto focus and other functions;

系統設計,機台規劃,製程開發,整線輸出 歡迎來電洽詢

業務經理 張先生 0933264536

Line : pabmike EMAIL:mike@buft.com.tw