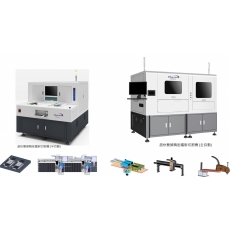

This machine is mainly used for laser cutting, drilling, and windowing of FPC, PCB, ceramic substrate, PI film, copper foil,Stainless steel,Titanium alloy and other thin film metal sheets, 3C circuit board modules, chip package circuit boards, etc. The dual-head dual-platform laser cutting machine can achieve Automatic feeding, automatic cutting and sorting of LGA. High-precision laser processing for different product applications in the 3C industry, the communications industry, and ODM/OEM and other industries. Refined laser processing for materials with ultra-high requirements such as cutting edges and dust carbonization, with standard communication interface SMEMA, which can be customized according to the different needs of customers.

設備特色:

Ø光源模組化設計:可根據不同產品應用搭配綠光、紫外等超快雷射器;

Ø多種加工模式自由切換:離線式、搭配自動上下料板機、產線線上式等;

Ø高速橋式雙運動平臺:Cycle Time效率更高,提高生產效率和產能;

Ø採用直線電機加光學尺全閉環驅動加工平臺,易維護,精度高:

Ø智慧視覺應用:CCD自動對位識別各類Mark點,同軸視覺同步檢測識別等應用特點;

Ø便捷的軟體操作:標準SMEMA介面,支援遠端控制和資料上傳,檔識別等;

Ø自主研發創新的雙風口除塵模組,保證產品表面的潔淨度,減少加工過程中產生的污染;

Ø配置機械手分揀上下料結構,減少人工作業,大幅提高產能和品質.

ØLight source modular design: according to the application of different products with green, UV and other ultra fast laser;

ØA variety of processing mode free switching: offline, with automatic loading and unloading machine, production line online, etc;

ØHigh speed bridge dual motion platform: cycle time is more efficient, improving production efficiency and capacity;

系統設計,機台規劃,製程開發,整線輸出 歡迎來電洽詢

業務經理 張先生 0933264536 Line : pabmike EMAIL:mike@buft.com.tw